New

Premium Black & White

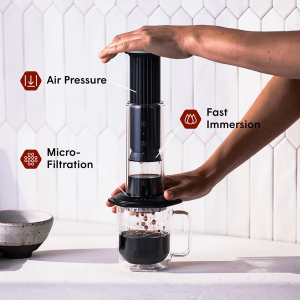

Our iconic 3 in 1 brewer handcrafted in double wall borosilicate glass and metal

Brew Faster. Taste Better.

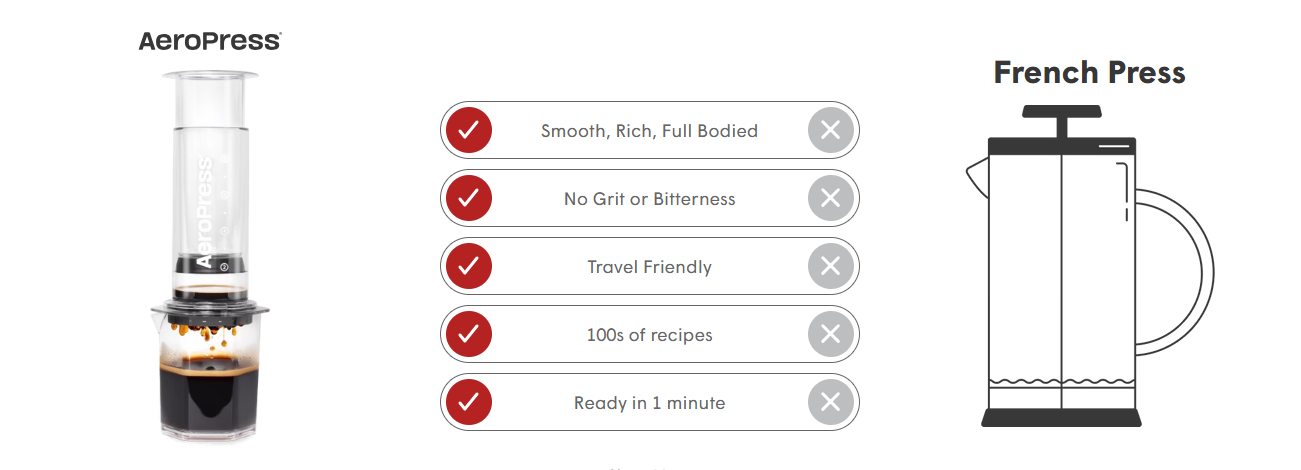

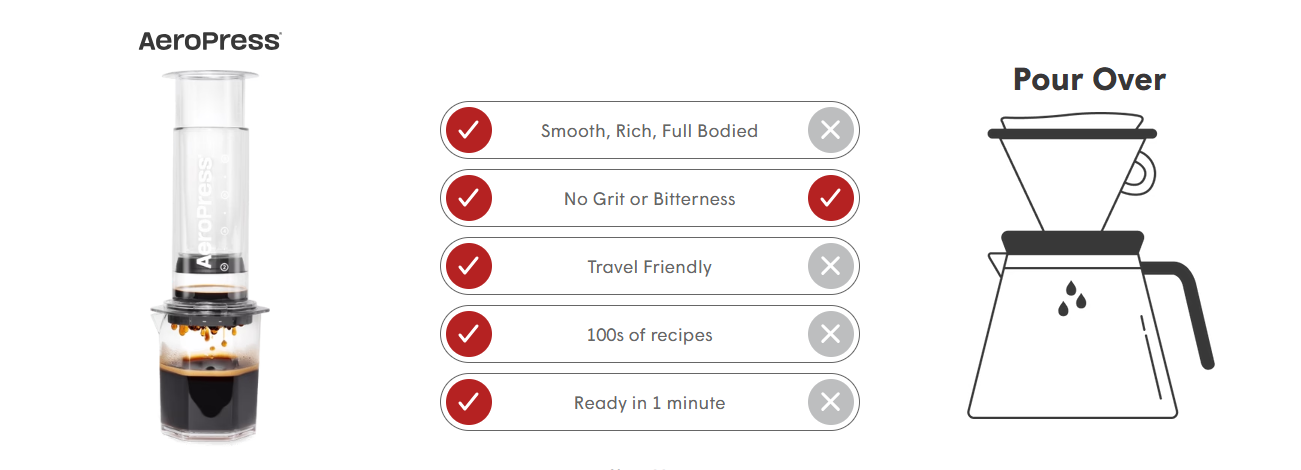

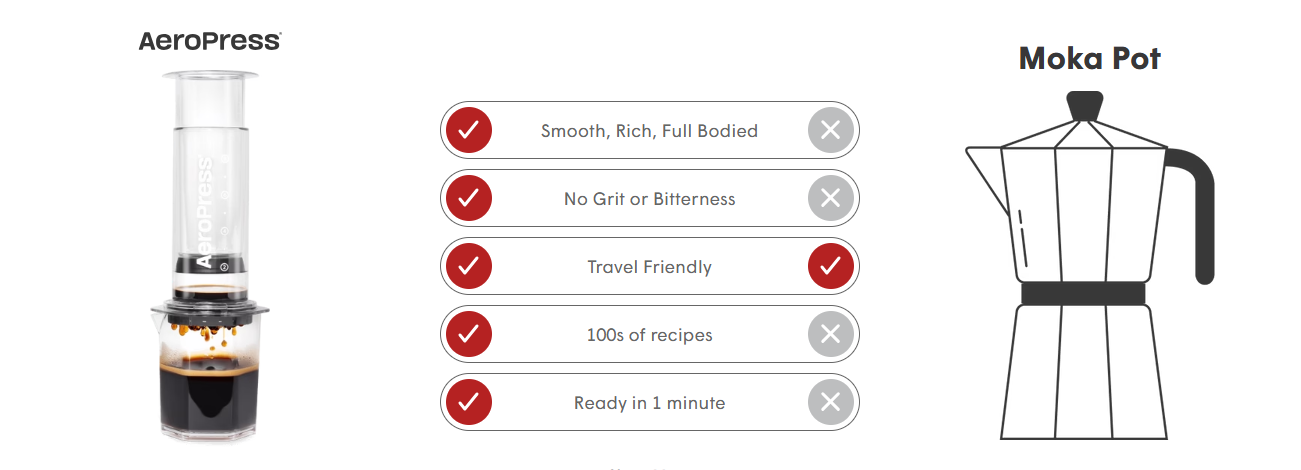

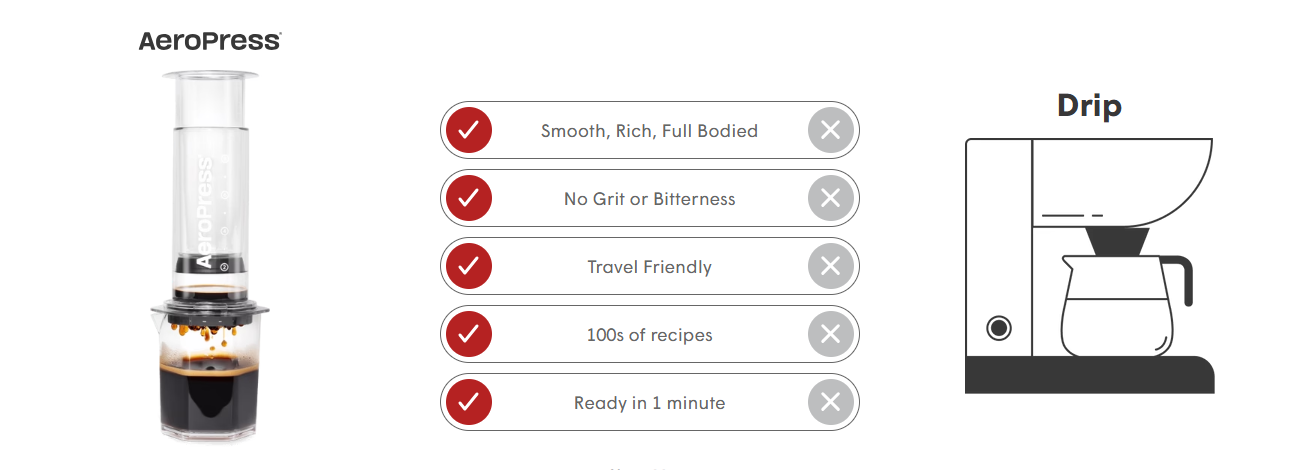

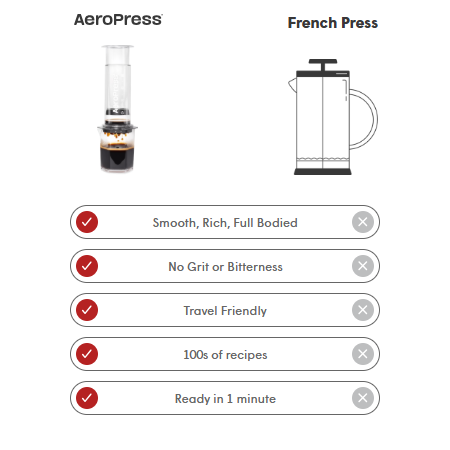

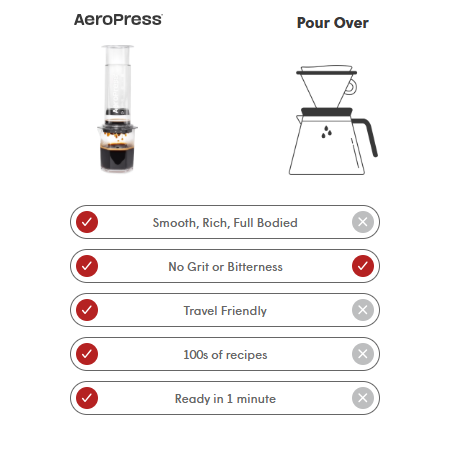

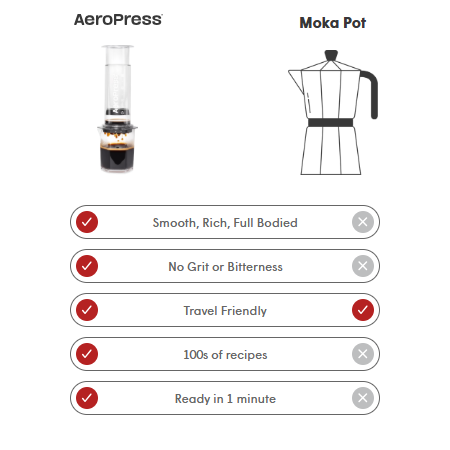

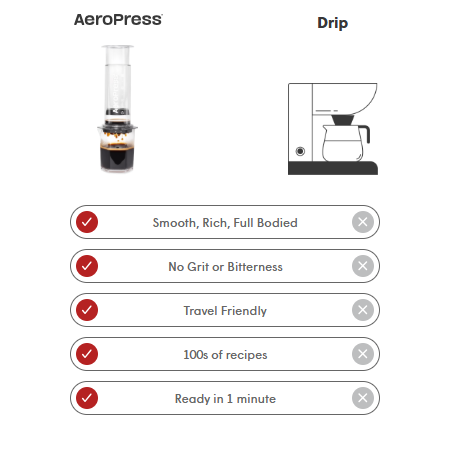

How Do We Stack Up?

Press for Better Coffee

The AeroPress Kitchen

AeroPress Tropical Coffee Amaretto Sour

Coffee • Gin • Yuzu Juice

Homemade Almond Milk Cold Brew with AeroPress Go Plus

Coffee • Almond Milk • Ice

AeroPress Strawberry Latte

Coffee • Strawberry • Milk

Maple Pecan AeroPress Latte

Coffee • Pecan • Milk

Baratza Vario W+ with AeroPress

Coffee • Water

Ube Einspänner AeroPress Latte

Coffee • Ube Extract • Cream

AeroPress Pistachio Honey Iced Latte

Coffee • Pistachio • Milk

Espresso Martini with Tequila and Salted Caramel

Coffee • Tequila • Caramel

Espresso Martini with Vanilla Recipe

Coffee • Vodka • Vanilla

AeroPress Iced Boo-Berry Matcha Latte Recipe

Coffee • Matcha • Milk

Experience Aeroprass

Classic Recommendation.

The Engineer’s Approach: Decoding the Science Behind Extraction

This article will delve into the technical mechanisms, physics, and material science that govern how different brewing devices achieve their results, focusing on the core principles of solubility and temperature.

To appreciate the sheer complexity of a seemingly simple preparation process, one must look beyond the gleaming exterior of the brewing apparatus and into the physics governing its operation. At its heart, brewing is a sophisticated chemical process involving solubility and mass transfer. We are essentially using hot liquid to selectively dissolve desirable flavor compounds from a finely fragmented solid. The device’s role is to control the variables that maximize this desired extraction while minimizing the release of less pleasant ones.

The fundamental principle is the relationship between temperature and solubility. Generally, the hotter the liquid, the faster the dissolution rate of compounds. However, the brewing sweet spot is narrow. The water acts as a solvent, pulling hundreds of different compounds—including acids, melanoidins, and various carbohydrates—from the grounds. Too cool, and the process is stalled, leaving a thin, sour beverage dominated by early-extracted acids. Too hot, and the rate of extraction becomes runaway, releasing compounds that contribute to bitterness and an acrid mouthfeel. A precisely engineered device utilizes a high-quality heating element, often a thermocoil or a boiler, coupled with temperature sensors to maintain the liquid within the ideal $90^circ C$ to $96^circ C$ range. The stability of this temperature throughout the entire brewing cycle is a hallmark of superior engineering.

The second critical physical mechanism is flow dynamics and saturation. For uniform extraction, every particle of the raw material must be contacted by the hot solvent for roughly the same duration. This is where the design of the brewing chamber or filter basket becomes crucial. In drip systems, a well-designed dispersal head ensures the hot liquid is showered evenly over the entire bed of grounds, preventing dry pockets or localized over-extraction channels (known as “channeling”). In pressurized systems, like those used for concentrated beverages, the apparatus must distribute the high-pressure liquid uniformly across the packed disc of material. Any inconsistency leads to channeling, where the liquid finds the path of least resistance, resulting in a wildly uneven taste profile.

The material science of the device itself also plays an often-overlooked role. Components that come into contact with the hot liquid must be chemically inert. This is why high-grade stainless steel, specific engineered plastics, or ceramic materials are preferred. Materials that leach flavor or retain residual oils will compromise the delicate aromatic compounds in the prepared beverage. Furthermore, the design of the internal pipework is engineered to minimize heat loss—a small temperature drop between the boiler and the dispensing head can have a noticeable impact.

Consider the steam component, essential for preparing milk-based drinks. The steam wand, or frothing mechanism, requires the machine to convert liquid rapidly into a gas—a process requiring significant energy and pressure. Effective steam production is not just about heat; it’s about the volume and force of the vapor. A well-designed system generates dry steam, high in temperature and low in suspended liquid droplets, which creates the velvety, micro-textured milk necessary for a truly professional finish.

Ultimately, the best brewing device is a triumph of engineering over variability. It takes the inherent inconsistencies of natural ingredients and uses physics and precise mechanical control to yield a consistently perfect output. Understanding the underlying science—the dance between temperature, pressure, flow rate, and contact time—transforms the user from a passive consumer into an active conductor of a sophisticated chemical reaction. The machine is the laboratory, and the daily brew is the delicious, perfectly calibrated result.